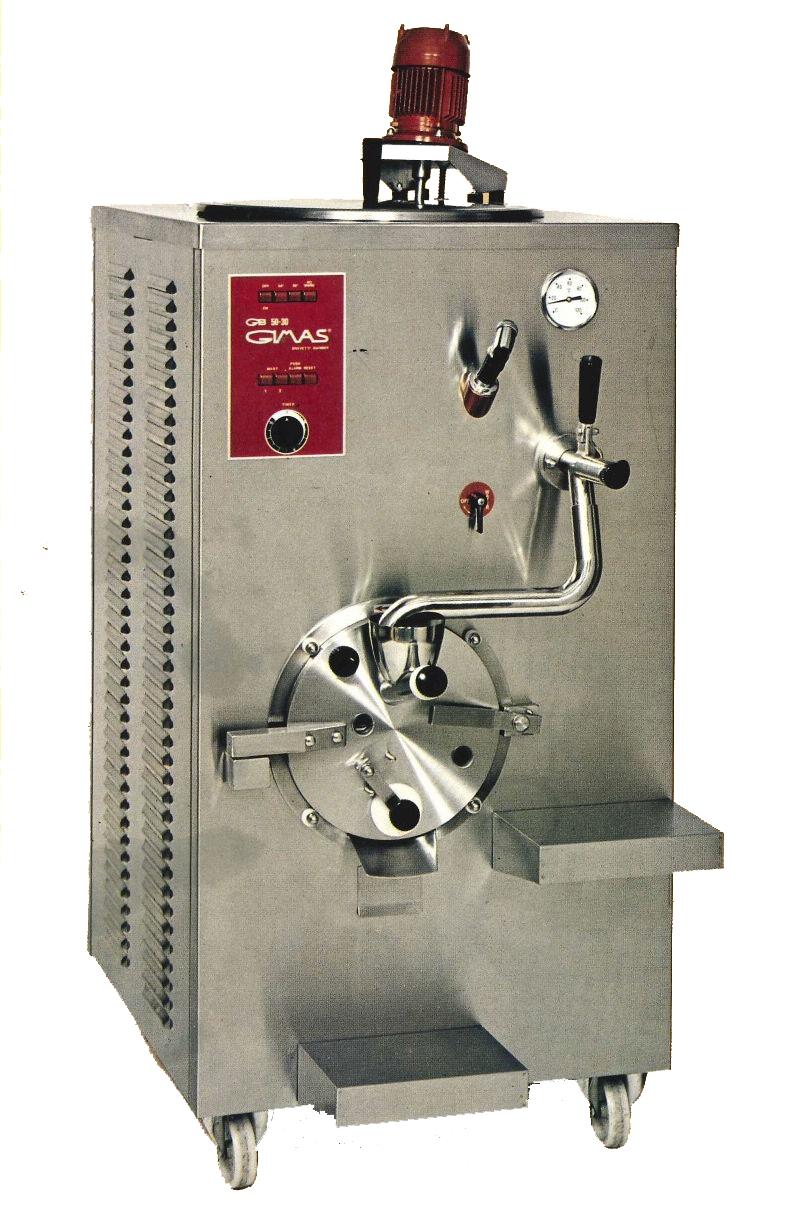

GIMAS GB 50/30 Ice-Cream Machine

GB 50/30

CG 50/30 is a combined machine of very small sizes composed of one pasteurizing appliance of 50 lt. and one whipping appliance of 45 lt. / h.f.p. , entirely built in stainless steel , in compliance with the strictest international hygienically rules.

It is scheduled for small and middle ice-cream shops and solves all ice-cream shops and solves all ice-cream maker’s problem producing Italian whipped ice-cream with extreme simplicity.Some very new patents allow to GB 50/30 to transfer from pasteurizing to whipping appliance the pasteurized mixture without any manufacture.

During pasteurizing cycle can be put into whipping appliance fruit mixtures or other flavours and ice-cream can be produced at the same time. This high output machine can make up to 17 different ice-cream flavours.This is one of the advantages of versalitily fo GB 50/30 .This machine is provided for an electrical installation of 380 Vlot/50 Hz. On demand , it can be delivered for a currente of 220 Volt/50Hz.

GENERAL CHARACTERISTICS

After pouring the wished quantity of mixture into the tank, never exceeding the level gauge (minimum 30 litres) press the starting button on-off (1) scheduling the wished cycle by pressing the button (3) of the temperature 85°C or 65°C according to the product to be pasteurized.From this moment starts the pasteurizing cycle preceding the follow:

Start the mixer engine (9) getting the quickest movement of the mixture, opening at the same time the electro valve enabling the entrance of the water for the water-bath heating. This electro valve will remain opened for one and half minute for enabling the complete filling of the whole circuit (the first time we suggest to check that the outlet of the discharged water is free);after the one an half minute the electro valve for water inlet will close and will start the heating which will stop anly when the temperature of the scheduled cycle will be reached.In case of cycle 85°C, the resistances for heating will burn out and the electro valve of water inlet will open for cooling.

If the cycle is 65°C, the resistances will burn out and the mixture will remain at this temperature 20 minutes long , after that the electro valve of water inlet will open for cooling until 35°C;( this is common for both pasteurization cycles).At 35°C the water electro valve will close and starts the refrigerating unit lowing the temperature up to 4°; the refrigerating until will stop and the mixer engine (9) will invert the rotation direction for enabling the slow movement of the pasteurized mixture to be matured.

PHONE NOW TO BOOK AN INSPECTION … BE QUICK MOBILE PHONE: WILLIAM 0404 605 236